Advanced intralogistics, much more than just an added benefit

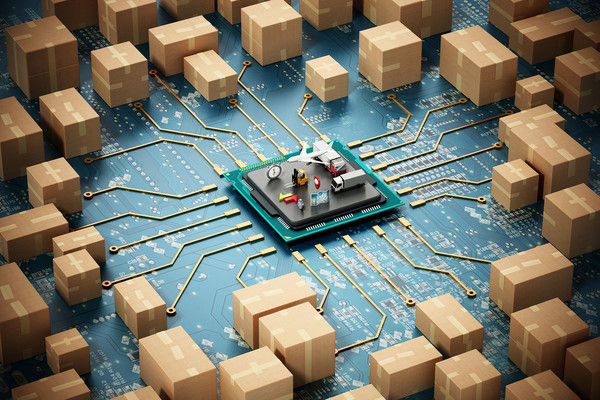

Advanced intralogistics and logistics deliver value that may not be visible in the finished product but is a key component of industrial processes that take place in large, busy warehouses.

These technologies are becoming increasingly crucial aspects for the quality and sales performance of any company, especially those operating in the field of capital goods and industrial automation. The equation is simple: the greater the efficiency of logistics, the bigger the improvement in productivity, sales and revenues.

Like all aspects relating to production lines, intralogistics has undergone a series of significant developments and innovations in recent years that are radically transforming companies’ operating methods. These latest developments mainly concern process optimisation, automation, sustainability and data integration. Let’s take a closer look:

- Advanced automation: industrial logistics is experiencing a revolution thanks to the emergence of advanced automation. Robots and autonomous vehicles are becoming increasingly widely used in warehouses and production facilities, speeding up the movement and handling of goods, reducing operating costs and improving overall efficiency. Another new development concerns new-generation automatic high-bay warehouses, which are designed to save space, save time and optimise stock management. Dedicated integrated software allows for constant tracking of products, instruments and stored raw materials, reducing errors and offering modular solutions with ergonomic and customised configurations.

- IoT and live tracking: the Internet of Things (IoT) applied to industrial logistics enables real-time monitoring of goods and equipment. By using new digital applications, it is possible to keep track of goods in transit, detect potential issues or damage and optimise delivery routes

- Big Data and predictive analysis: companies are increasingly relying on predictive analysis to optimise inventory management, plan shipments and reduce downtime. This enables the company’s management to make more rational decisions based on objective data, thereby saving both time and money

- Environmental sustainability: attention to sustainability remains crucial in every area of industry, including logistics. Companies are working to reduce their CO2 emissions and minimise the environmental impact of their operations. This includes adopting eco-friendly vehicles and packaging, as well as using dedicated software to plan more efficient routes and reduce fuel consumption.

- Blockchain: Blockchain technology is emerging as a promising solution for improving transparency and security in the supply chain. It is capable of securely recording transactions and tracing the origin of products, thereby reducing the risk of fraud and counterfeiting.

- Drones and autonomous deliveries: Drones and self-driving vehicles are becoming increasingly widely used for deliveries. These technologies promise to reduce delivery times and costs, especially in remote or congested areas.

- Integration and collaboration: Systems integration and collaboration between the various parties involved are key aspects throughout the entire supply chain. Optimal integration and collaboration ensure more effective communication between suppliers, manufacturers and distributors, thereby improving the responsiveness and flexibility of the entire logistics chain.

To conclude, industrial logistics is undergoing a number of highly significant transformations thanks to automation, data analysis, sustainability and new technologies. These developments are helping companies to maximise the efficiency of the entire production, shipping and sales cycle and to reduce costs and environmental impact, thereby securing a more competitive future in the increasingly innovation-driven global market.